Matte Jewellery is quite popular in European Countries. It is a kind of low key styles, looks soft and great.

How we make matte surface on jewellery?

First,we finish all the previous jewellery making steps, then choose the right size of glass sand. There are different sizes of glass sand, then it will come out different matte surface like below.

Tiny matte Thick matte

Using this machine to do water sandblasting, most of our items are small, we need to use hand pen to hold those to control the whole pcs is well done.

After sandblasting, the jewelry pcs will go to plate step. Then the whole step is done.

Any interest about our matte jewellery, welcome to email us inquiry@rfsilver.net ,thanks.

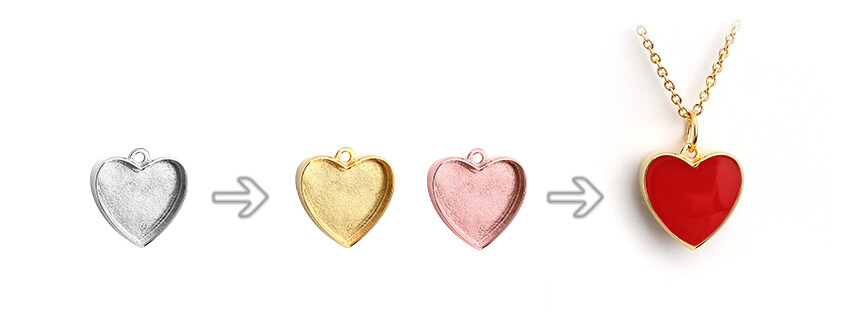

When our simple mounting findings come cross with the enamel filling or milk filling, it will bring us into a changeable and wonderful journey.

Enamel filling: Enamel is the process of applying a decorative color coating to metal, using a powder and high temperatures. It is a very popular craft during jewellery making. The huge colours and diverse patterns available enable to make jewellery very nice and pretty.

(photo from our customer’s work,cannot copy the designs)

We don’t introduce how it makes and its long long history here. But we make a basic guide on all new custom enamel jewellery to help you to understand our working steps, which let your custom enamel sterling silver jewellery journey made easily here.

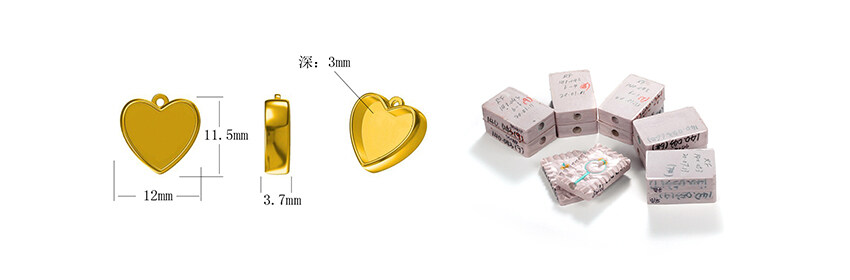

1.Design jewelry shape like heart, round, square or ball etc.

2.Choose Pantone colors, rough effect looking and plating color, your logo and logo position (may or not), send us all those information.

3.We make CAD drawing for your confirm, and then make mother mold.

4.Make mass production sample,finish plating,make enamel color,send you photo or sample to finally confirm.

5.After your confirmation,we make mass production,pack them and ship out.

Welcome to send us your inquiry for any enamel jewelry you want to make,surely you would have great and smooth journey with us.

Slider Jewellery started about 6 years ago.Our company was the first batch to make slide craft. As the end customers can adjust the length easily by themselves. Customers got crazy at them. We got huge success for this collection. Here we have a bit introducing about this magic slide craft.

Silicone is a polymer made up of siloxane. They are typically colorless, oils or rubber-like substances. Silicones are used in sealants,adhesives, lubricants, medicine, cooking utensils, and thermal and electrical insulation. Their good elasticity help us to achieve this function (slide and adjust length easily)

1.Basic version--machine made round bead and roundel slider bead

We are using different sizes silicone tubes into the silver bead, to match different thickness of chain. One size of silicone can be applied to chains with a difference 0.3-0.5mm from top to bottom.

This type is widely used in bracelets and necklace because of its low cost and less limits on designs.

2.High version--More design styles and nice finishing

We had many different sizes, shapes and different silicone sizes to add the beauty of jewellery. Slider bead is not only for slide function, also core design and beauty part.

Those can greatly improve the grade and quality feeling of jewellery. Those are the designers’ and brands’ favorite.

3.Custom version--Design your own slider bead (Exclusive one)

We accept custom design slider bead, it will work like below steps.

Your design brief & chain sizes --- confirm silicone availability --- make CAD drawing and 3D printing sample --- test silicone and chain working --- make mold --- test mold --- make production.

For any inquiry about slider, welcome to email us at inquiry@rfsilver.net, hope you can find your favourite slider jewellery.

Shiny Surface is the mostly wide used in jewellery making. Some findings come with glossy, no need extra treatment like tube, wire and beads etc.

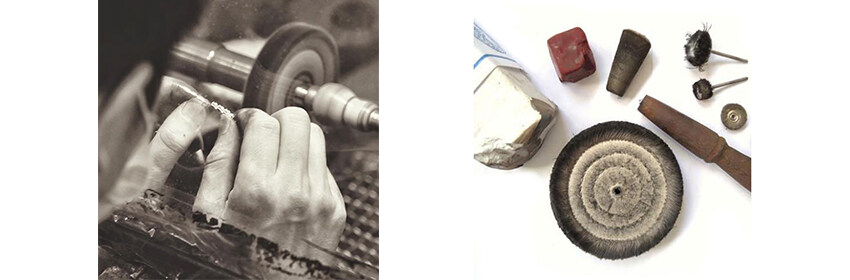

But what we want to introduce here is about high quality shiny, need man-hand do extra high polishing. For a lot of less quality jewellery, they only make with machine polishing.

First let’s see the difference between machine polishing and high polishing.

After compare, which one you will choose?

Definitely good quality ones. But how we work with high quality shiny jewellery? We need take careful control from the first step to the end packing, every step need good care.

1. Use good and high purity silver material to make casting or stamping ( if the silver with impurity or not melt well, surely we won’t get good result)

2. Get good care during casting, the shiny jewellery need different temperature and time to do casting, these shiny ones will be together separately, not mix with other styles.

3. After previous step, we need to hand-polishing by buff. It may take 2 or 3 different tools depending on the item shapes.

4. Take those to plate, also need to be very careful, as the shiny surface is so easy to get scratch.

5. After Quality checking, we need to cover the shiny part with electrostatic film and one in polybag.

For any default ones, the above steps(3-5) need to do again. If 1-2 steps are not right, then we can only redo again. So usually we will have small quantity test first for big quantity orders.