Shiny Surface is the mostly wide used in jewellery making. Some findings come with glossy, no need extra treatment like tube, wire and beads etc.

But what we want to introduce here is about high quality shiny, need man-hand do extra high polishing. For a lot of less quality jewellery, they only make with machine polishing.

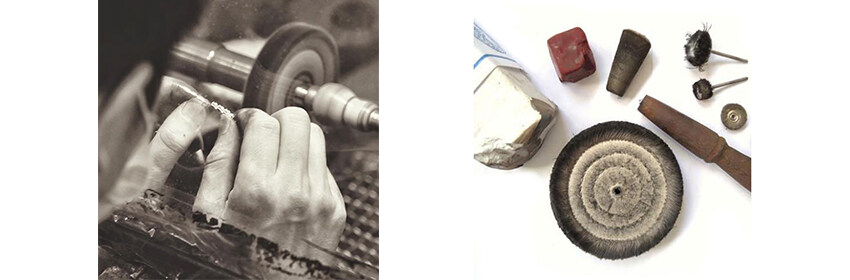

First let’s see the difference between machine polishing and high polishing.

After compare, which one you will choose?

Definitely good quality ones. But how we work with high quality shiny jewellery? We need take careful control from the first step to the end packing, every step need good care.

1. Use good and high purity silver material to make casting or stamping ( if the silver with impurity or not melt well, surely we won’t get good result)

2. Get good care during casting, the shiny jewellery need different temperature and time to do casting, these shiny ones will be together separately, not mix with other styles.

3. After previous step, we need to hand-polishing by buff. It may take 2 or 3 different tools depending on the item shapes.

4. Take those to plate, also need to be very careful, as the shiny surface is so easy to get scratch.

5. After Quality checking, we need to cover the shiny part with electrostatic film and one in polybag.

For any default ones, the above steps(3-5) need to do again. If 1-2 steps are not right, then we can only redo again. So usually we will have small quantity test first for big quantity orders.